As winter approaches, cities across the country have ushered in a rapid cooling mode. Outdoor screens standing on streets and alleys are also experiencing a silent extreme cold challenge.

From giant screens in commercial centers to advertising players on street corners, they cannot be tucked into pockets for warmth like mobile phones. So, how do these screens maintain stable display in freezing conditions?

Part 1: The Unbearable "Freeze" for Screens

Most advertising screens on the market have a minimum operating temperature set at -20°C, meaning they can work normally in most cold regions.

LED Screens: Condensation Damages Components

The components of outdoor LED displays, including masks, PCBs, and module kits, undergo inconsistent physical dimensional changes in low-temperature environments due to differences in the shrinkage coefficients of different materials. This change may lead to fractures in the cabinet connection structure.

During operation, LED screens generate a certain amount of heat, resulting in a relatively high internal temperature. When the external ambient temperature drops sharply, the screen's shell and internal metal components cool down rapidly, forming cold spots.

This drastic change, similar to breathing on cold glass, causes condensed water droplets to form quickly and adhere to the surface of the display's PCB boards and modules. Without proper waterproofing, these components are highly susceptible to corrosion.

LCD Screens: Prolonged Liquid Crystal Response Time

For LCD screens, low-temperature environments significantly affect their performance. In low temperatures, the liquid crystal molecules inside the screen may transform from a flowing nematic phase to a crystalline or glassy state, where the energy of molecular motion decreases sharply.

When the temperature drops to its phase transition point (generally around -20°C), the viscosity of the liquid crystal material increases significantly, and the speed of molecular arrangement and rotation slows down, leading to prolonged response time.

◎ Demo of ghosting on LCD screen mobile phones in low temperatures.

In this case, the screen becomes sluggish like a frozen finger. An LCD screen originally with a 4-millisecond response time may have a delay of tens of milliseconds in extreme cold environments, resulting in obvious afterimages in dynamic images.

Part 2: Hardware-Level Protection for Screens to Survive Winter Safely

To enable an electronic screen to survive in severe cold, it is far from enough to rely solely on endurance. Comprehensive hardware protection from the outside in is required, equivalent to customizing an exclusive "polar suit" to prevent the screen from failing due to low temperatures.

Equipment Selection: Low-Temperature Resistant Materials

Ordinary carbon steel becomes brittle at low temperatures, while high-strength alloy materials with excellent low-temperature resistance can withstand the load of snow and ice accumulation and the impact of strong winds, reducing the risk of damage caused by physical pressure.

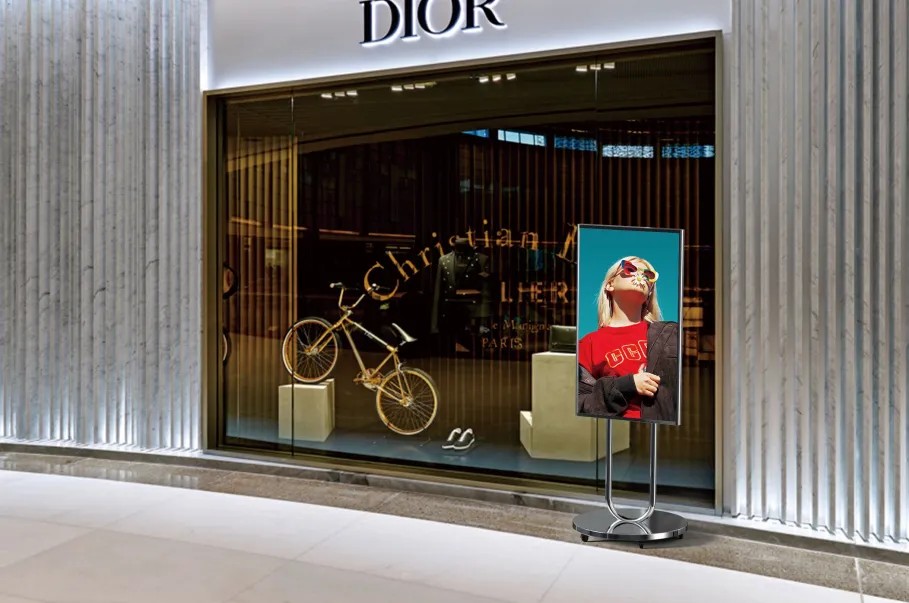

For LCD screens, the liquid crystal material is crucial. The LCD advertising screens produced by Yimeijisi can operate stably in winter in most regions.

For extremely cold areas, we also offer the option of wide-temperature liquid crystal materials.

◎ iMGS LCD advertising players, adapting to a wide range of climatic conditions.

Heating Modules: "Warm Clothing" for the Screen

An automatic temperature-controlled heating module can be installed inside the display, with a set temperature threshold. When the ambient temperature is lower than the threshold, the heating module starts automatically, and shuts down when the temperature rises.

This active heating method can effectively maintain the internal temperature of the screen, avoiding damage to electronic components or performance degradation caused by low temperatures.

Protection Level: Isolating External Rain and Snow Intrusion

The IP65 protection level can effectively block the intrusion of external rainwater, snow, and melted ice water. This design usually includes high-quality silicone seals and waterproof connectors, forming a multi-layered protection mechanism.

Even if a small amount of moisture intrudes, it can ensure that the core circuits are not corroded, extending the service life of the equipment.

The hardware defense for screens to survive winter safely is an interlocking system: low-temperature resistant materials resist harsh external environments; intelligent temperature-controlled heating forms a circulation system to maintain internal temperature; and high-level protection constitutes a dense barrier to isolate rain and snow intrusion.

Part 3: How to Use Outdoor Screens Properly in Low-Temperature Conditions?

In low-temperature conditions, hardware is the foundation for the stable operation of outdoor screens, and proper use and maintenance are also key to the screen's "cold resistance".

Give the Screen a Warm-Up Period

In extremely cold weather, avoid turning on the screen at full brightness directly. The correct approach is to first power it on at low power for preheating, and then gradually adjust to full brightness for operation.

This step allows the temperature of internal components to rise steadily, avoiding physical stress caused by rapid thermal expansion and contraction, and at the same time evaporates any trace moisture that may exist inside, eliminating the risk of short circuits.

Avoid Long-Term Static Display

Low temperatures reduce the movement activity of liquid crystal molecules, leading to a significant slowdown in their response speed. If an LCD screen displays a fixed image for a long time, the risk of afterimages is greatly increased.

In outdoor scenarios, dynamic screensavers can be used to play full-screen changing animations instead of only small-area changes, to effectively drive the movement of liquid crystal molecules across the entire screen.

Remote Monitoring for Preventive Maintenance

With cloud-based broadcasting and control technology, real-time monitor key parameters such as the internal temperature, humidity, and power supply status of the screen. Once abnormal humidity increase is detected with the risk of condensation, heating or an alarm can be automatically triggered, allowing operation and maintenance personnel to perform remote intervention.

The stable operation of outdoor screens in low temperatures relies not only on their own hardware foundation but also on reasonable standardized operation and maintenance, which provides soft protection for the long-term use of the screens.

From a practical perspective, although low-temperature weather brings many challenges, it is an unavoidable reality, after all, outdoor areas are common locations for screens.

Technological progress is bridging the challenges brought by low temperatures. Screen manufacturers including Yimeijisi are continuously innovating and optimizing technology to make the screen's tolerance limit higher and higher, ensuring that it can still meet the needs of commercial and information dissemination even in low-temperature and extreme cold working conditions.